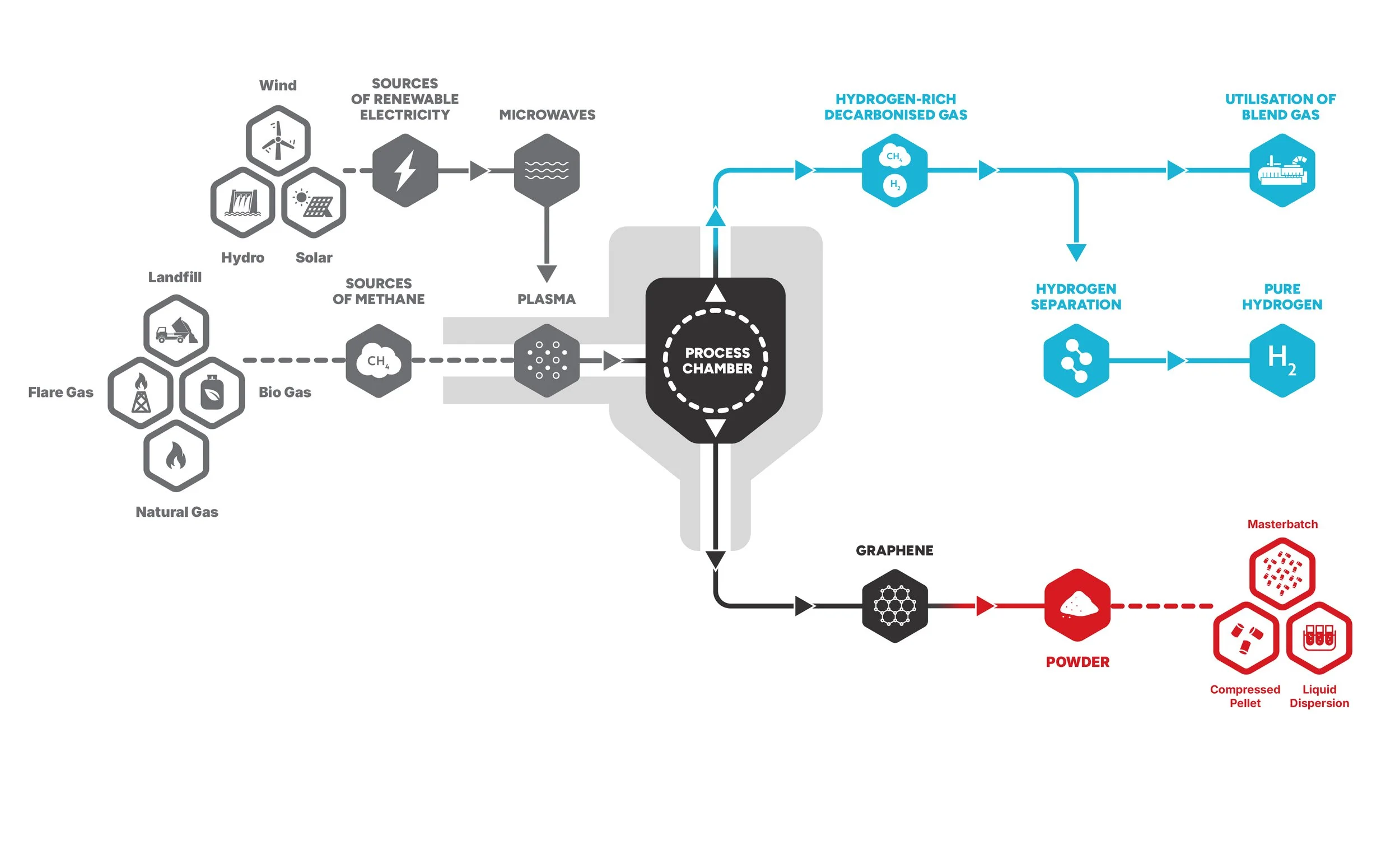

LOOP generates high-quality graphene and clean hydrogen via pre-combustion carbon capture.

Taking methane (CH₄) from a variety of sources, LOOP uses microwave plasma technology to split it into solid carbon (C), in the form of high-quality graphene, and a hydrogen-rich gas blend that can be used as a lower-carbon fuel or purified to clean hydrogen (H₂).

This patented, highly controlled process allows Levidian to deliver graphene with the quality, consistency, volume and cost that makes advanced materials adoption practical across more industries than ever.

Benefits

Create new value: graphene for advanced materials applications; a hydrogen-rich gas blend or purified hydrogen for heat and/or power; and carbon reduction to support decarbonisation goals.

Self-contained and efficient: low temperature, low pressure, catalyst-free and water-free, powered by electricity.

Modular and scalable: designed as a self-contained unit that can be retrofitted to existing infrastructure and deployed or redeployed anywhere with a methane source.

Where LOOP is used

Heavy Industry

Oil & Gas

Wastewater Treatment

Large-scale Agriculture

Product evolution

LOOP Gen1

Proven in the field across gas types and operational environments. Available in multiple configurations sized by input gas mass-flow. Modular scaling proven from LOOP20 to LOOP60 to LOOP100, delivered from proven supply partners in the UK and US.

LOOP Gen2

~20x times more productive than Gen1, LOOP Gen2 is designed to produce ~15 tonnes of graphene per nozzle each year, making this super-material more accessible, scalable and cost-effective. The first Gen2 unit is operational at our Cambridge Technology Centre, with additional units planned from 2026.

R&D Focus

We continue to scale LOOP’s gas-processing capacity and output efficiency to meet industrial demand. This includes ongoing development to increase graphene yield, hydrogen output and electrical efficiency across different gas compositions.

How it works (at a glance)

LOOP uses focused microwaves (electromagnetic energy) to ionise methane into a plasma, enabling the separation of hydrogen and carbon before combustion.

Input: methane (biogas/biomethane, landfill gas, natural gas, flare or process gas)

Outputs: graphene (solid carbon) and a hydrogen-rich gas blend or purified clean hydrogen

Why choose LOOP

Independent credentials: Statement of Feasibility from DNV.

Verified graphene quality: Levidian is a recognised Verified Graphene Producer (from the Graphene Council) with independently characterised material and robust quality control.

Clear value pathways: Supported routes to graphene buyers, plus hydrogen use options.

Credible economics: Value stacking from graphene + hydrogen + avoided-carbon costs.

Deployment path

Book a feasibility discussion

Technology

Our core process is a form of methane splitting that uses microwave plasma to process gas pre-combustion.

Industries

Levidian supports organisations across industries to realise the benefits of advanced materials and achieve their decarbonisation goals.

Graphene Products

Need graphene powder? Ready to trial functionalised powders, dispersions, or masterbatches? Levidian provides standardised, reproducible solutions to help you unlock graphene’s benefits.