How it works

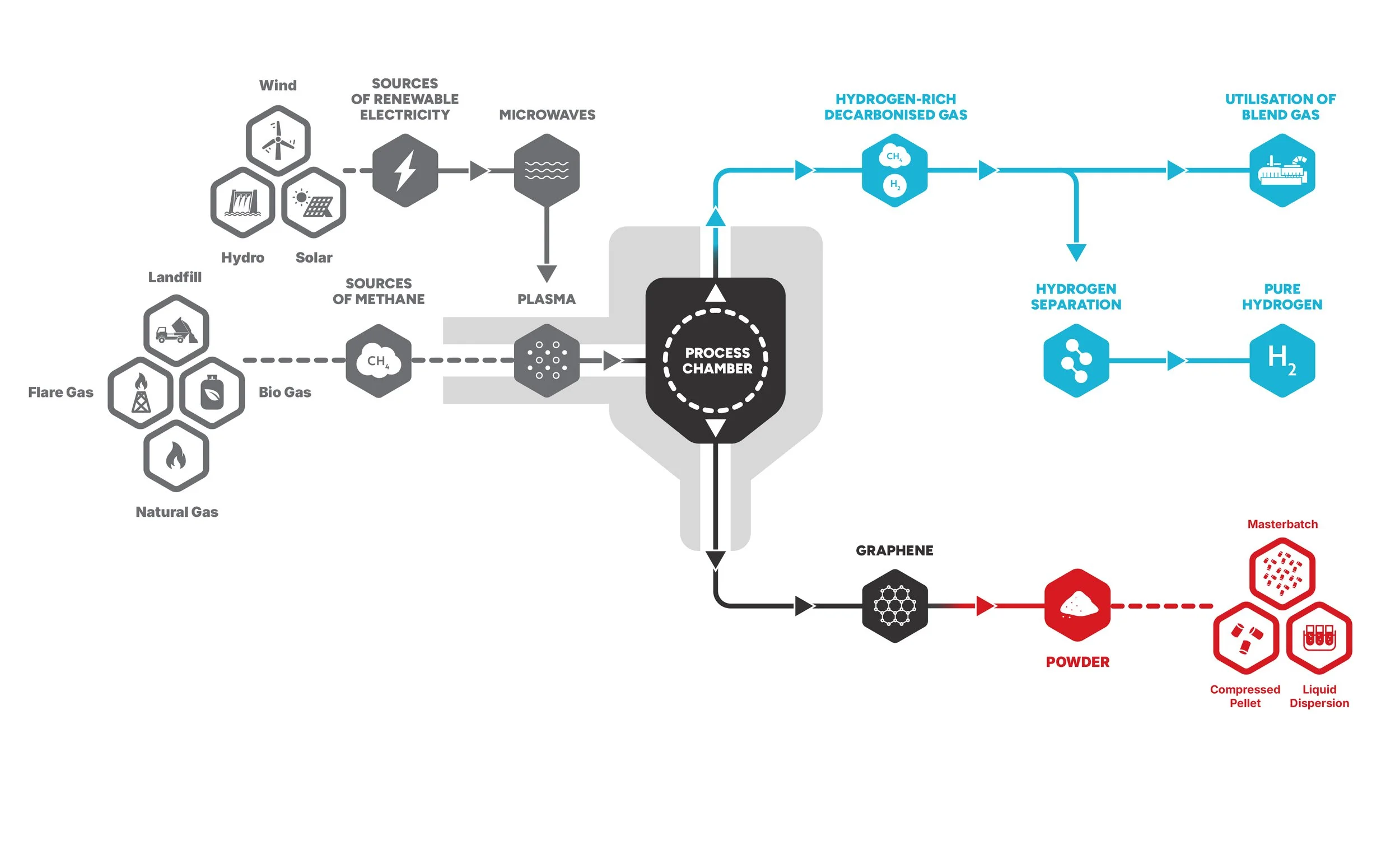

At the heart of LOOP sits a unique ‘nozzle’ where methane is ionised into a plasma. High frequency electromagnetic microwaves energise electrons in the gas and promote collisions with other molecules, breaking them apart and generating more free electrons and positive ion radicals. This creates a cascade of reactions, which ensures a sustained plasma state and a highly stable graphene production method.

In the LOOP method, the methane is the plasma, with most of the energy contained in microwaves delivered directly to the electrons and ions of the gas. As these excited electrons and ions exit the plasma region, they cool and combine to stable compounds, principally molecular hydrogen gas and solid carbon particles in the form of graphene.

Frequently Asked Questions

-

No. The process is water-free and catalyst-free.

-

No. Plasma torches use plasma primarily to heat the reactor. LOOP turns the methane itself into a plasma, directly energising the gas to drive bond breakage and recombination.

-

Biogas/biomethane, landfill gas, natural gas and suitable process or flare gases. Specific composition and flow ranges are confirmed during feasibility.

-

Typical biogas contaminants (for example CO₂, H₂S, moisture, siloxanes and VOCs) are assessed against tolerance bands. Pre-treatment or polishing may be specified case by case.

-

At present, LOOP is optimised to produce graphene nanoplatelets (GNPs) but longer-term, there is scope to create different types of carbons and process different types of gas.

-

Graphene is collected and routed into advanced-materials applications such as polymers, coatings, concrete and batteries. Offtake routes and buyer introductions can be supported.

-

The initial hydrogen output is a hydrogen-rich blend gas which can be combusted in compatible engines or turbines to generate onsite low-carbon electricity or heat, or purified and stored for future use.

-

Tie-ins normally include gas inlet, electrical supply, off-gas handling, graphene off-take and hydrogen routing. Footprint, utilities and access are covered in the site-requirements brief.

-

A HAZID/HAZOP is performed during integration. Availability targets, maintenance intervals, spares and training for site teams are provided as part of deployment planning.

-

Yes. Units are modular and can be added in parallel to increase throughput or redeployed as needs change.

-

Carbon is captured before combustion as a solid material (graphene). Full accounting depends on system boundaries, gas source and electricity mix. Using biogenic methane sources can enable significant net CO₂e reductions and, in some configurations, net-negative outcomes within defined system boundaries.

-

Electrical load is specified during feasibility based on target throughput and site conditions. Remote monitoring and SCADA integration can be discussed where relevant.

-

Timelines depend on site readiness, permitting and commercial arrangements. A typical path is feasibility, integration design, commercial and offtake planning, then installation and commissioning.

Interested in deploying LOOP?

Get in touch today to discuss your requirements with one of our LOOP experts.